In one of our previous blogs, we discussed the difference between single and two stage hand pumps. We focused on the difference between the two types, and when one was more advantageous than the other. In today’s blog, we will discuss how to size and choose the correct pump for your application.

PowerX has many different types and sizes of hydraulic pumps. The typical categories are hand pumps, air hydraulic pumps and electric pumps. Each category has an array of different flow characteristics and tank sizes. This information is critical when choosing the correct hydraulic pump for the application. Understanding the oil capacity of the cylinder or tool you are going to drive and the energy resources in your environment will help you make the right decision.

First, let’s look at the environment you will be working in. If you are in a remote area and do not have access to electricity or compressed air, using a PowerX hand pump is probably your best solution. PowerX hand pumps come in many different oil capacities and stroke speeds. All of this information is available here. However, if shop air or electricity is available, then using one of PowerX’s air hydraulic or electric pumps can be a great solution. Each product was designed with durability and longevity in mind, withstanding some of the harshest environments. PowerX’s air hydraulic pumps start with a usable oil capacity of 37 in3 and go all the way up to 460 in3. (2 gallons). They are an economical solution for applications where multiple cycles of the hydraulic cylinder or tool is required. Click here for more Information on our air hydraulic pumps.

PowerX’s electric pumps are available for larger lifting applications or for integration into machinery which requires repeatable and consistent tool activation. An example of this would be a hydraulic press. Our standard usable oil capacity starts at 1 ½ gallons and can go up to 10 gallons of usable oil for larger lift operations. View all of our electric pumps.

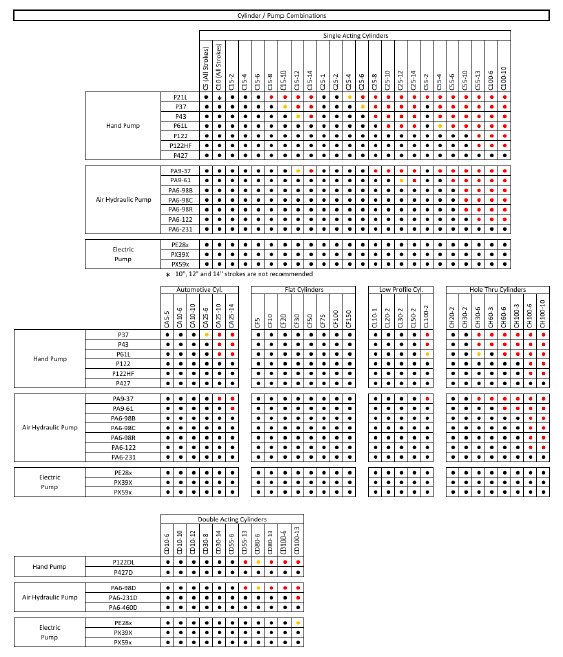

Once you have determined what type of pump your application requires, you then need to decide which size pump you need. This is done by calculating the usable oil needed by the cylinder/tool that will be actuated and then choosing a pump with the correct amount of usable oil in its reservoir. Sounds hard? Well, it actually is not that difficult, but it can be confusing. So, to help you with this process, PowerX has come up with a chart below to make your job much easier. Simply locate the size of the cylinder you will be using and follow the corresponding line back to the PowerX pumps. You can use any pump that has a black dot in the row. If the corresponding dot is red, that pump is not recommended. If you are using multiple cylinders, give one of our applications engineers a call at 1-888-922-1881 and they will help you with your system requirements.