High pressure hydraulics, Hydraulic pumps

Hydraulic Hand Pumps: What’s the Difference in our 10,000 PSI Single vs. Two-Stage Pumps

Looking for an alternative to Enerpac hydraulic pumps? Explore PowerX’s full line of manual hand pumps, built for performance and engineered for value. Customers often ask, “When do I need a two-stage hand pump versus a single-stage hand pump?” Well, that depends on the type of work you are trying to do inside your hydraulic system. There is a measurable difference between the two of them and both have benefits depending on the application. To help you make the right decision, let’s break down what a hydraulic hand pump is, explore how single– and two-stage pumps work, and discuss which one is best suited to your application.

What Is a Hydraulic Hand Pump?

Before we explore the difference between the two speeds of manual pumps, what are they in the first place? A hydraulic hand pump is a manual, non-electric tool that delivers reliable pressure for lifting, pushing, or pressing tasks—perfect for remote or power-limited job sites. This pump performs a straightforward task: it generates pressurized hydraulic flow to power a tool, then returns the fluid back to its reservoir. Lightweight and portable, it’s easy to transport and set up wherever you need it. Built-in pressure relief adds safety, while compatibility with smaller hydraulic cylinders makes it a versatile choice for construction, maintenance, and equipment repair work.

A hydraulic hand pump is a manual, non-electric tool that delivers reliable pressure for lifting, pushing, or pressing tasks…

Would I Need a Single-Stage Hand Pump?

First up are our simple Single-Stage Pumps, like our popular PowerX P43 Single-Stage 10,000 PSI (700 BAR) Hand Pump. This serves as a great option to operate a cylinder, ram, jack, puller, or a press. The reason why it is called a “single-stage” pump is because the flow of oil produced is the same on each stroke of the handle. For the PowerX P43, the flow is a continuous 0.20 in³ of oil per stroke. The pump’s flow rate remains constant, whether it is simply raising a single-acting cylinder with no weight on it, or pushing 10 tons at 10,000 PSI. A single-stage pump is great if your hydraulic ram does not have to travel far before it starts to lift or push the load.

However, when the cylinder or ram must travel a longer distance before contacting the load, a single-stage pump can become physically exhausting due to the number of strokes required to build pressure. This would get tiresome very quickly!

To see our P43 hand pump in-action, watch our video below!

Should I Choose a Two-Stage Hand Pump?

Enter the PowerX Two-Stage Pump, like the bestselling PowerX P37 “Two-Stage” 10,000 PSI (700 BAR) Hand Pump. A two-speed hydraulic hand pump offers advantages over single-

speed models for tasks like pressure testing, operating hydraulic presses, or working with long-stroke cylinders. Two-stage hydraulic hand pumps give the operator higher flow rates up until the cylinder or ram starts to do work. In the case of the PowerX P37 hand pump, the first stage has a flow of 0.79 in³ of oil per stroke (almost 4 times more than the P43) before making contact with the work load where the pressure builds. Once the ram contacts the load, and the pressure inside the system rises above 200 PSI, the second stage kicks in at 0.17 in³ of oil volume. This two-stage pump allows the operator to do less work (or hand pumping) before meeting the load. Your operators will thank you for better efficiency and ease of use!

This two-stage pump allows the operator to do less work (or hand pumping) before meeting the load.

Side-By-Side Comparison

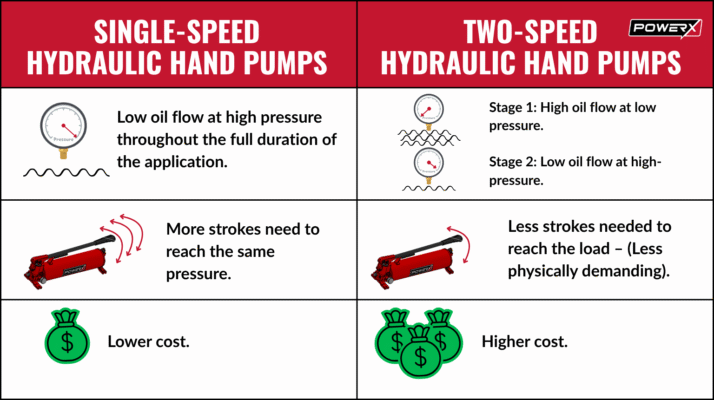

Single-speed hydraulic pumps deliver low flow at high pressure, making them a solid choice for smaller stroke cylinders, flange spreaders, and pullers. Two-speed hand pumps, on the other hand, offer faster flow at lower pressures and switch to lower flow as pressure builds; this is ideal for tools or cylinders that need to travel a distance before engaging in the actual task. In fact, some two-speed models can cut down handle strokes by up to 78% compared to single-speed versions. Both pump types come in a range of oil capacities and are available in configurations for single- or double-acting hydraulic tools.

Please view the graphic below for a visual representation.

Choosing the Right Pump for the Job Site

Environment matters. If you’re working in remote locations or power-restricted areas, hand pumps are a go-to solution. They’re fully manual, don’t require electricity or air, and are highly portable.

But how do you decide between pump types as your next job is approaching? Here are some common scenarios:

Single-Stage Variant:

Use a single-stage pump if you’re working with compact tools or cylinders that only need to move a short distance—like hydraulic pullers or lifting equipment where setup is minimal.

Two-Stage Variant:

Use a two-stage pump for tasks that involve longer cylinder travel, such as lifting large structures, operating presses, or conducting system pressure tests where time and effort matter.

With this information, you should be able to narrow down which version of manual pump would make more sense for the work that needs finished. Have more questions? Our team of experts has more resources available.

Still Need Help Finding the Right Fit for You?

To find the right-sized hydraulic pump for your lift, check out our catalog of pre-built options. It’s a complete guide to all our in-stock manual pumps, ready to ship and easy to compare.

PowerX International offers the expertise and high-quality hydraulic pumps you need for reliable lifting and pressing in the field or shop. Whether you’re working in remote locations or power-limited environments, our manual pumps deliver dependable high-pressure performance. Contact us at 414-988-6202 and elevate your high-pressure operations today.